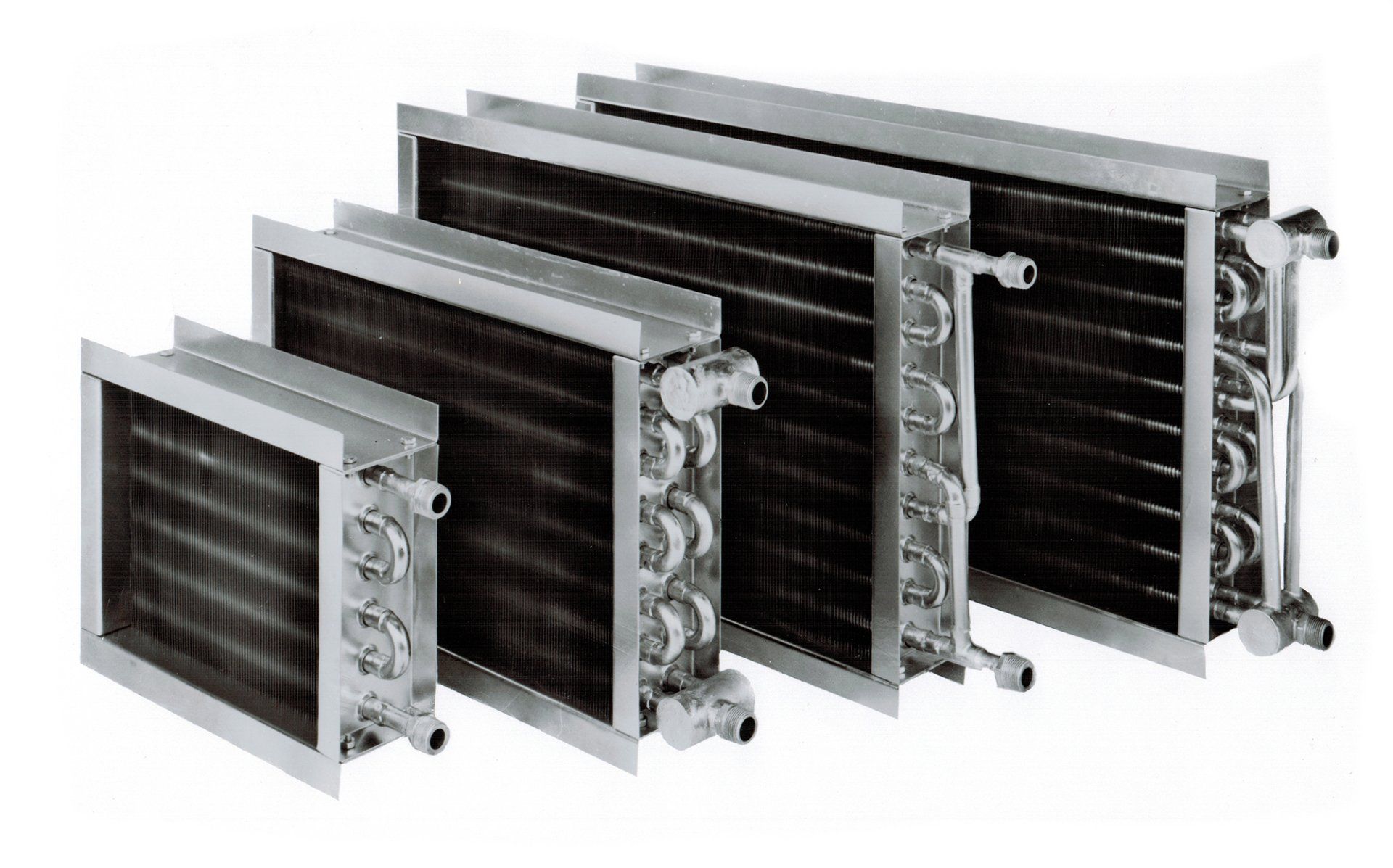

ASME Coils

Contact Us

ASME Coils

For any process or air comfort application

Industrial processes often require coils with features that exceed commercial grade HVAC coils. Industrial grade custom, replacement and special application heating and cooling coils can be manufactured. Anderson - Snow coils are available in a wide range of special materials and thicknesses designed to withstand the demands and abuse prevalent in industrial process applications.

Certified Materials

Anderson Snow uses the heaviest materials and all materials are mill certified.

Why Welded Coils?

All brazed coil joints are susceptible to pin hole leaks caused by internal or external corrosion/erosion, as well as, water hammer, and poor condensate drainage. Welded joints will stand up far longer and provide a far stronger joint.

ASME "U" Stamp

American Society of Mechanical Engineers - Coils meet the requirements of the ASME Boiler and Pressure Vessel Code for Unfired Pressure Vessels Under Section VIII/Division 1 of the code.

NBIC "R" Stamp

The National Board of Boiler & Pressure Vessel Inspectors - Coil repairs and/or alterations meet the requirements of the ASME Boiler and Pressure Vessel Code for Unfired Pressure Vessels under Section VIII/Division 1 of the code.

| Welding Process

|

|||

| Technical Description | Welding Terminology | Welder's Description | ANSCOR Description |

| Oxyacetylene (OAW) | Gas Welding | Gas Weld | Gas Weld |

| Shield Metal-Arc (SMAW) | Arc Welding | Stick Weld | Arc Weld |

| Gas Tungsten Arc (GTAW) | Heliarc | Tig Weld | Tig Weld |

| Gas Metal-Arc (GMAW) | Mig Welding | Wire Weld | Mig Weld |